Strong 90S-D2

Thumbnail 1

Thumbnail 2

Thumbnail 3

Thumbnail 4

Thumbnail 5

STRONG 90S-D2

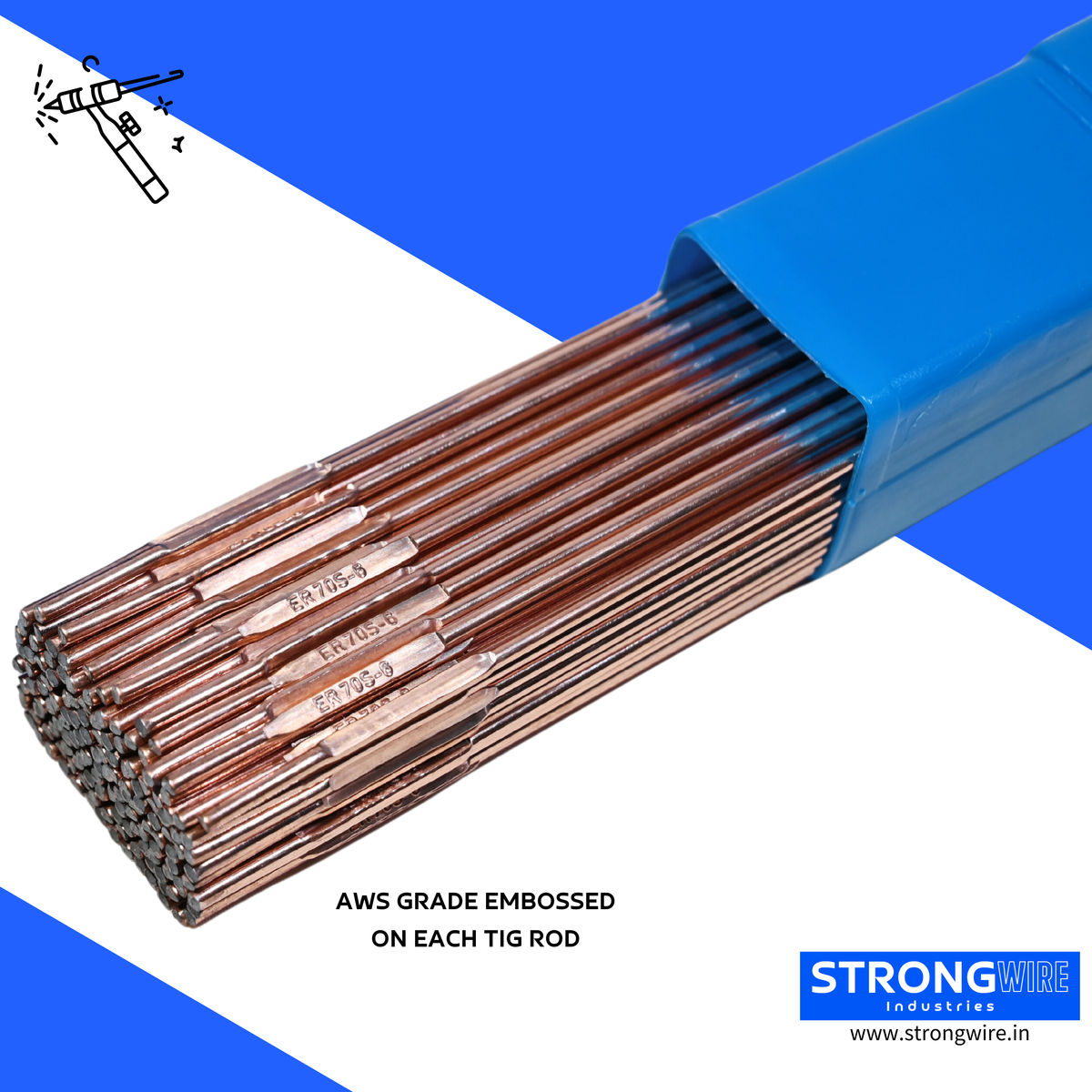

Copper Coated Solid Wire For MIG & TIG Welding

STRONG 90S-D2 is a low alloy steel welding wire that gives stable arc, smooth welding

performance and deposits radiographic quality welds. This wire is recommended for welding

of high strength fine-grained structural steels containing molybdenum (~0.5%).

STRONG 90S-D2 is highly suitable for welding low-alloy steels with high tensile strength and

creep-resistant steels. Suitable for pipelines and pressure vessels with operating

temperatures of about 500°C. This wire is also suitable for the repair of medium strength steel

castings.

-

Chemistry

- All Weld Mechanical Properties

- Packaging Specification

TYPICAL WIRE CHEMISTRY (%)

| C | Mn | Si | P | S | Cu | Ni | Cr | Mo | V |

|---|---|---|---|---|---|---|---|---|---|

| 0.07- 0.12 | 1.60- 2.10 | 0.50- 0.80 | 0.025 MAX | 0.025 MAX | 0.50 MAX | 0.15 MAX | 0.15 MAX | 0.40- 0.60 | 0.03 MAX |

| Required as per AWS 5.28 | Y.S MPa | U.T.S. MPa | ELONGATION % | IMPACT VALUE AT -30°C JOULE |

|---|---|---|---|---|

| Typical | ≥ 540 | ≥ 620 | ≥ 17 | ≥ 27 |

| 592 | 685 | 22 | 75 |

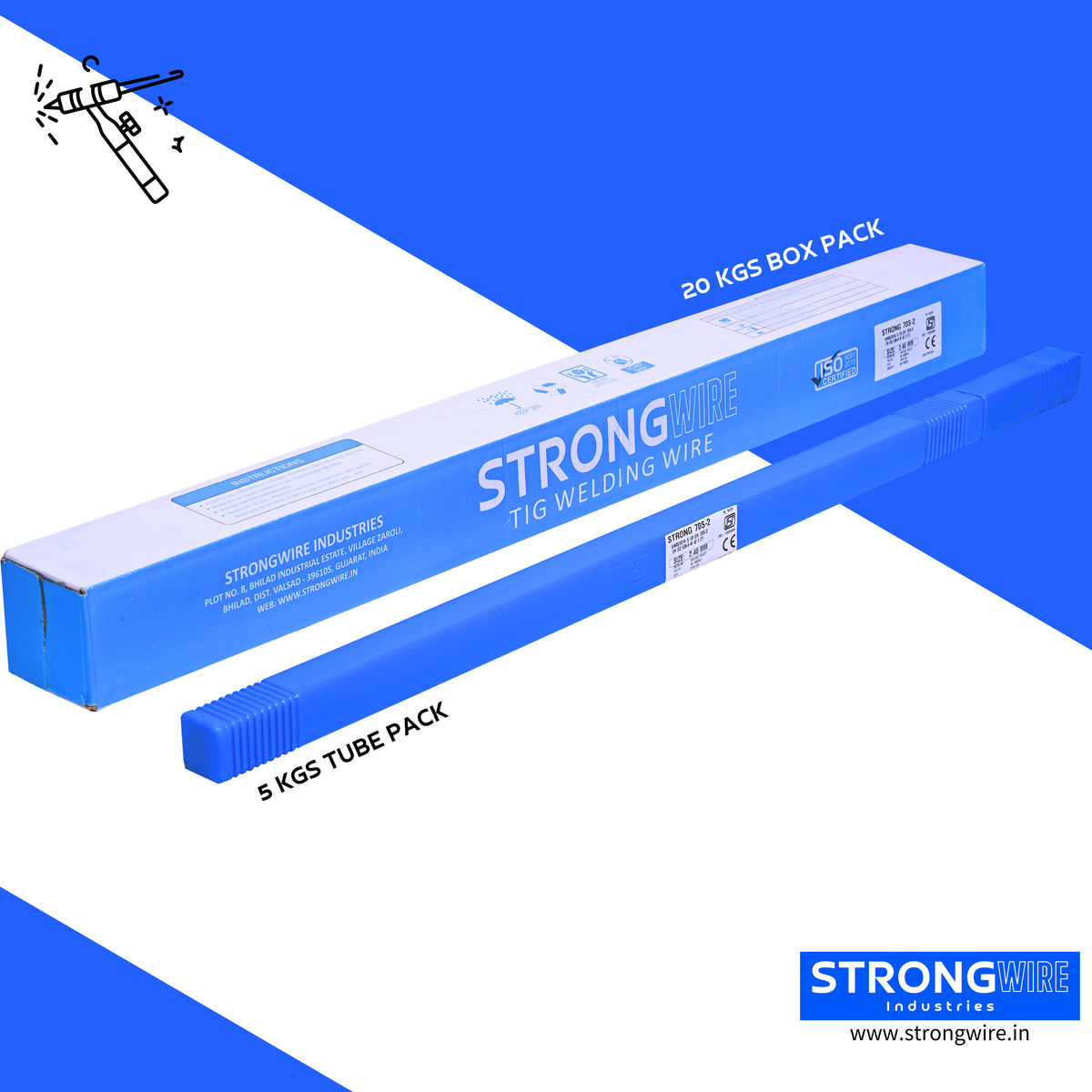

PACKAGING SPECIFICATIONS – MIG

DIA SIZE 0.80MM / 1.00MM / 1.20MM / 1.60MM / 2.00MM

SPOOL WEIGHT 1KGS / 1KGS / 5KGS / 12.5KGS / 15KGS / 17.5KGS

DRUM WEIGHT 100KGS / 100KGS / 150KGS / 250KGS / 300KGS / 350KGS

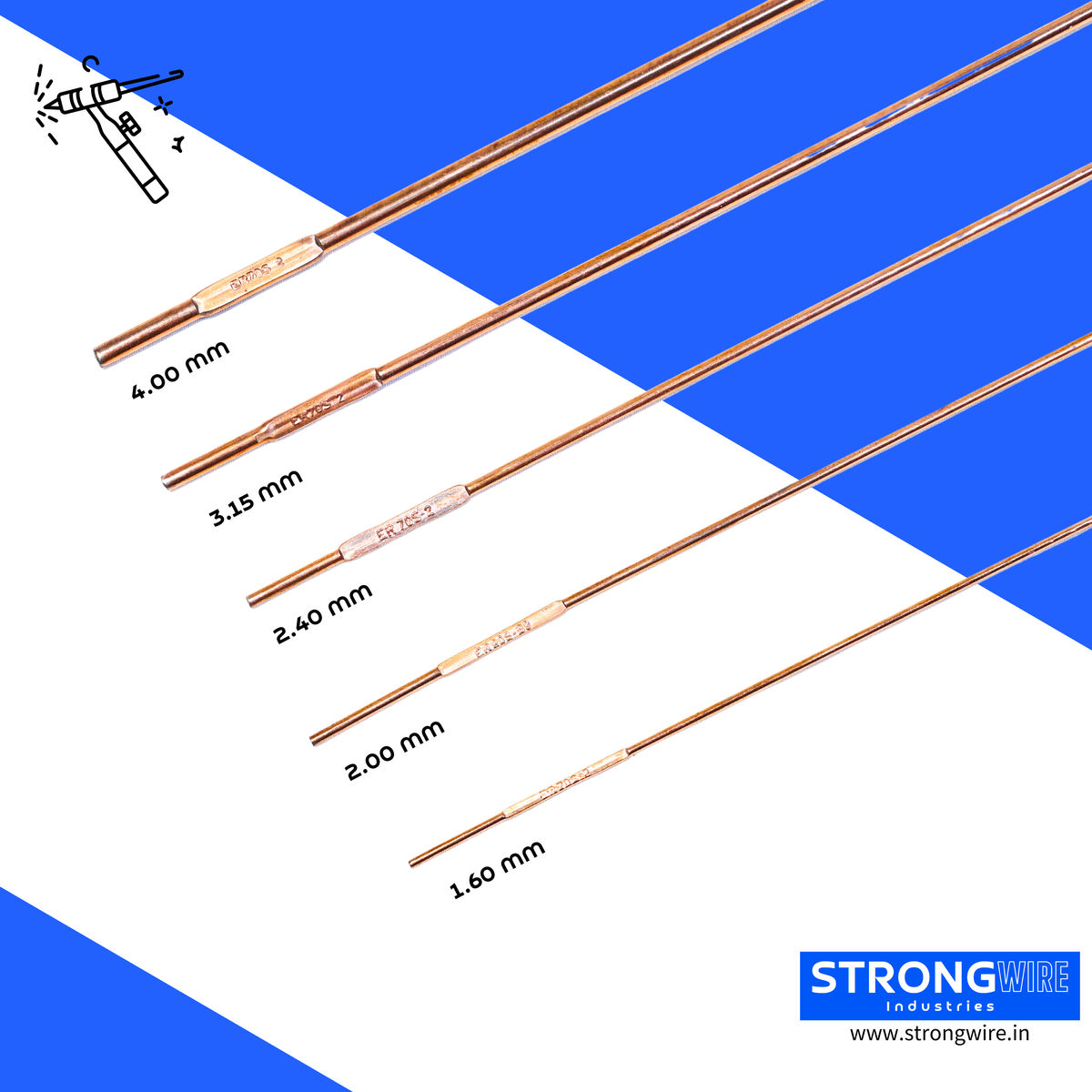

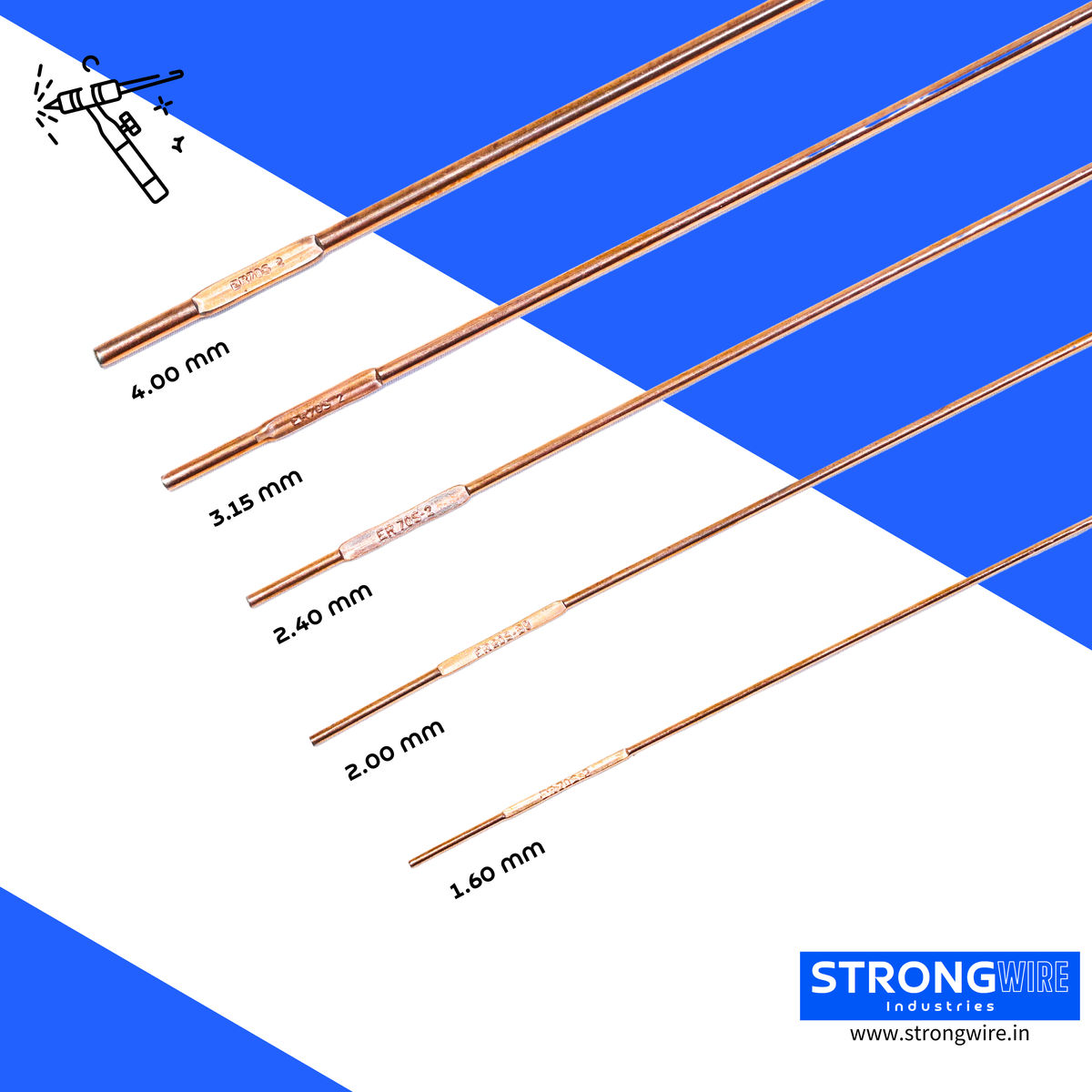

PACKAGING SPECIFICATIONS – TIG

DIA SIZE 1.60MM / 2.00MM / 2.40MM / 3.15MM / 4.00MM

WEIGHT 5KGS / 20KGS