- Schedule. Mon - Sat 10.00 - 18.00

Strong 70SG

Thumbnail 1

Thumbnail 2

Thumbnail 3

Thumbnail 4

Thumbnail 5

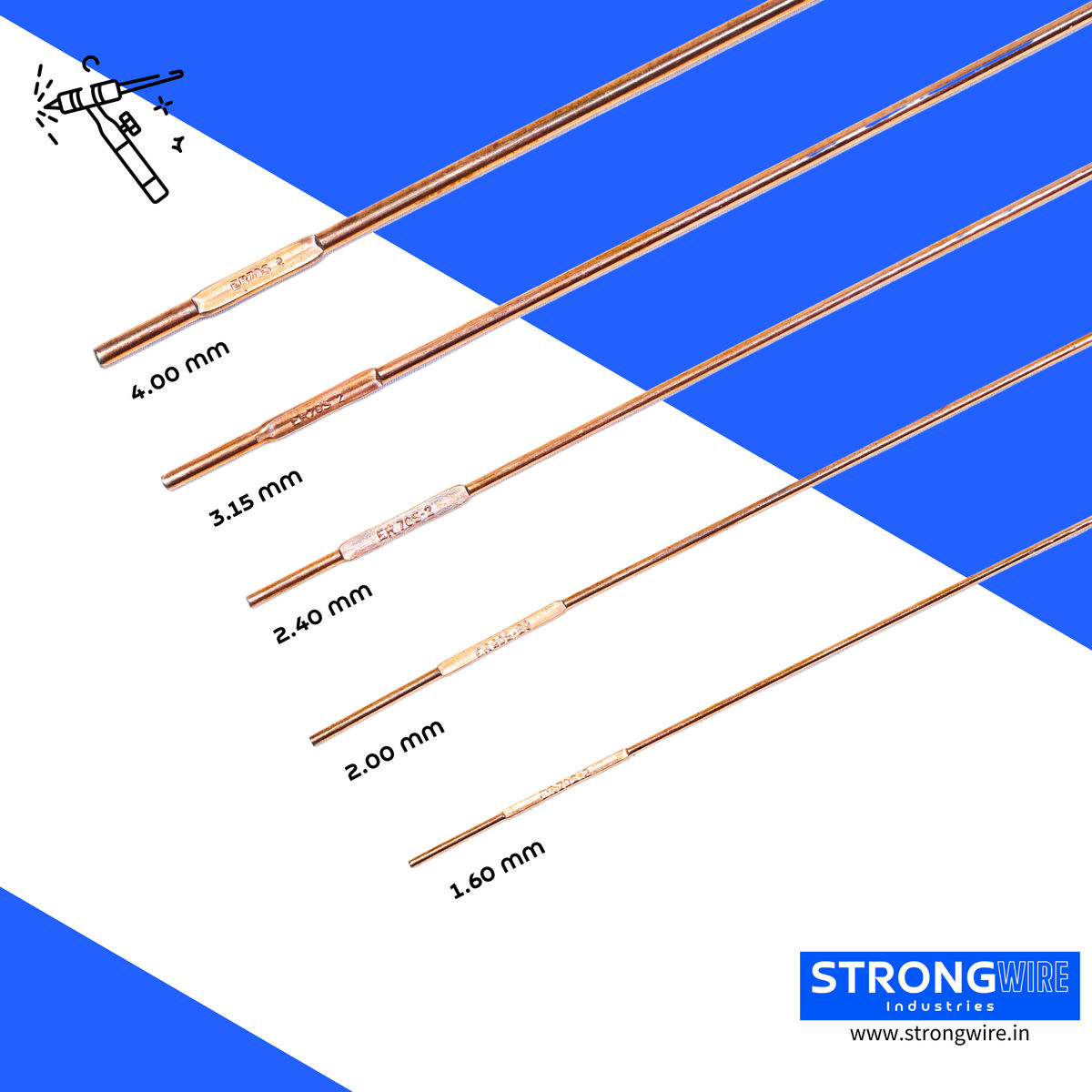

STRONG 70S-G

Copper Coated Solid Wire For MIG & TIG Welding

STRONG 70S-G is a copper coated low carbon steel wire with very low impurities and higher

levels of Manganese than typical low carbon steel wires for MIG & TIG welding.

It provides excellent weld bead appearance on flat or horizontal welding positions.

STRONG 70S-G can be used for general steel frame fabrication, automotive components, farm

equipment, construction equipment, pressure vessels, ship building and pipe fabrication.

Welders should avoid welding steels which have oil, mill scale, or other contaminants.

-

Chemistry

- All Weld Mechanical Properties

- Packaging Specification

TYPICAL WIRE CHEMISTRY (%)

| C | Mn | Si | P | S | Cu |

|---|---|---|---|---|---|

| 0.07-0.10 | 1.55-1.85 | 0.80-1.10 | 0.025 MAX | 0.025 MAX | 0.50 MAX |

| Required as per AWS 5.18 | Y.S MPa | U.T.S. MPa | ELONGATION % | IMPACT VALUE AT -30°C JOULE |

|---|---|---|---|---|

| Typical | ≥ 400 | ≥ 480 | ≥ 22 | ≥ 27 |

| 490 | 585 | 28 | 88 |

PACKAGING SPECIFICATIONS – MIG

DIA SIZE 0.80MM / 1.00MM / 1.20MM / 1.60MM / 2.00MM

SPOOL WEIGHT 1KGS / 1KGS / 5KGS / 12.5KGS / 15KGS / 17.5KGS

DRUM WEIGHT 100KGS / 100KGS / 150KGS / 250KGS / 300KGS / 350KGS

PACKAGING SPECIFICATIONS – TIG

DIA SIZE 1.60MM / 2.00MM / 2.40MM / 3.15MM / 4.00MM

WEIGHT 5KGS / 20KGS