- Schedule. Mon - Sat 10.00 - 18.00

Strong 70S-B2L

Thumbnail 1

Thumbnail 2

Thumbnail 3

Thumbnail 4

Thumbnail 5

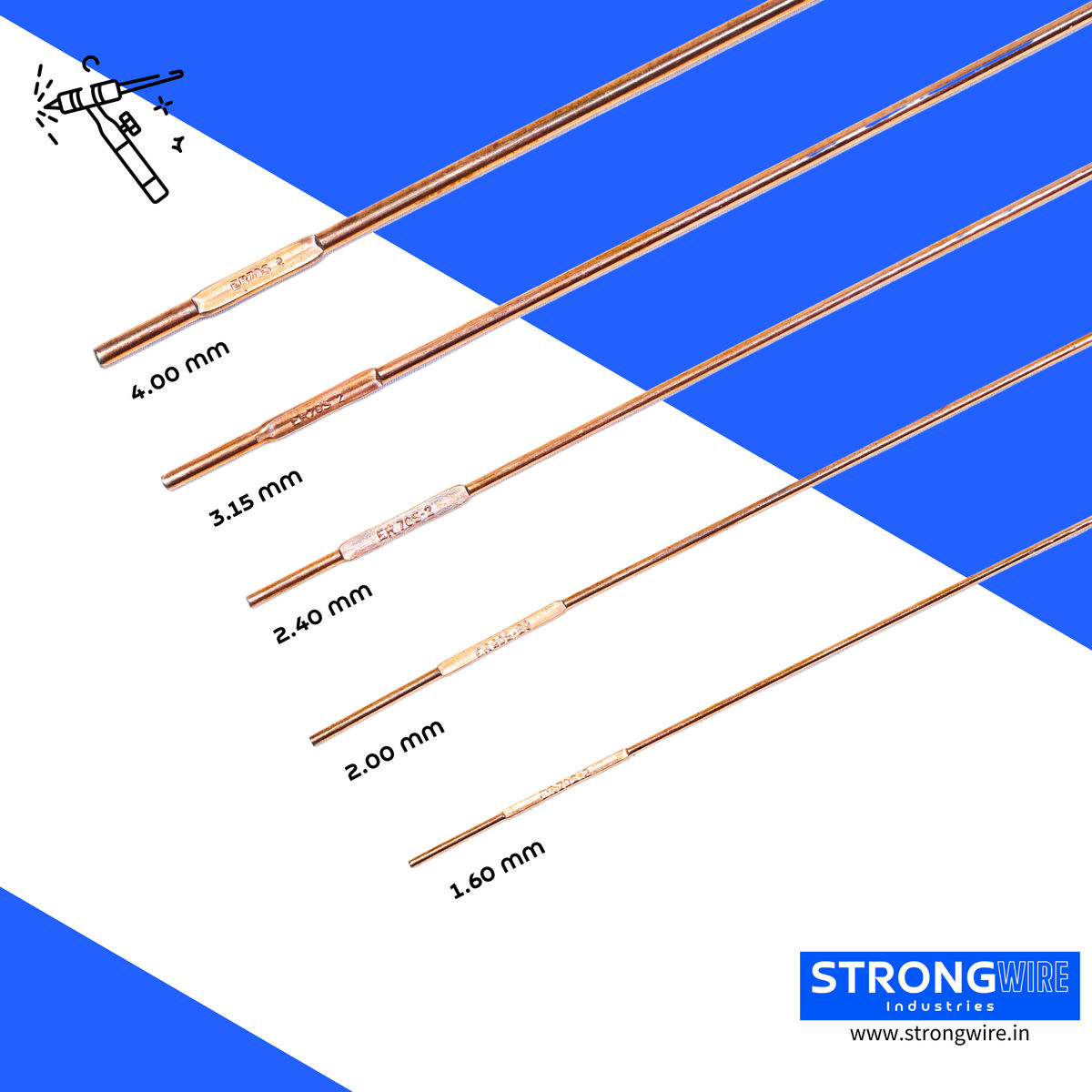

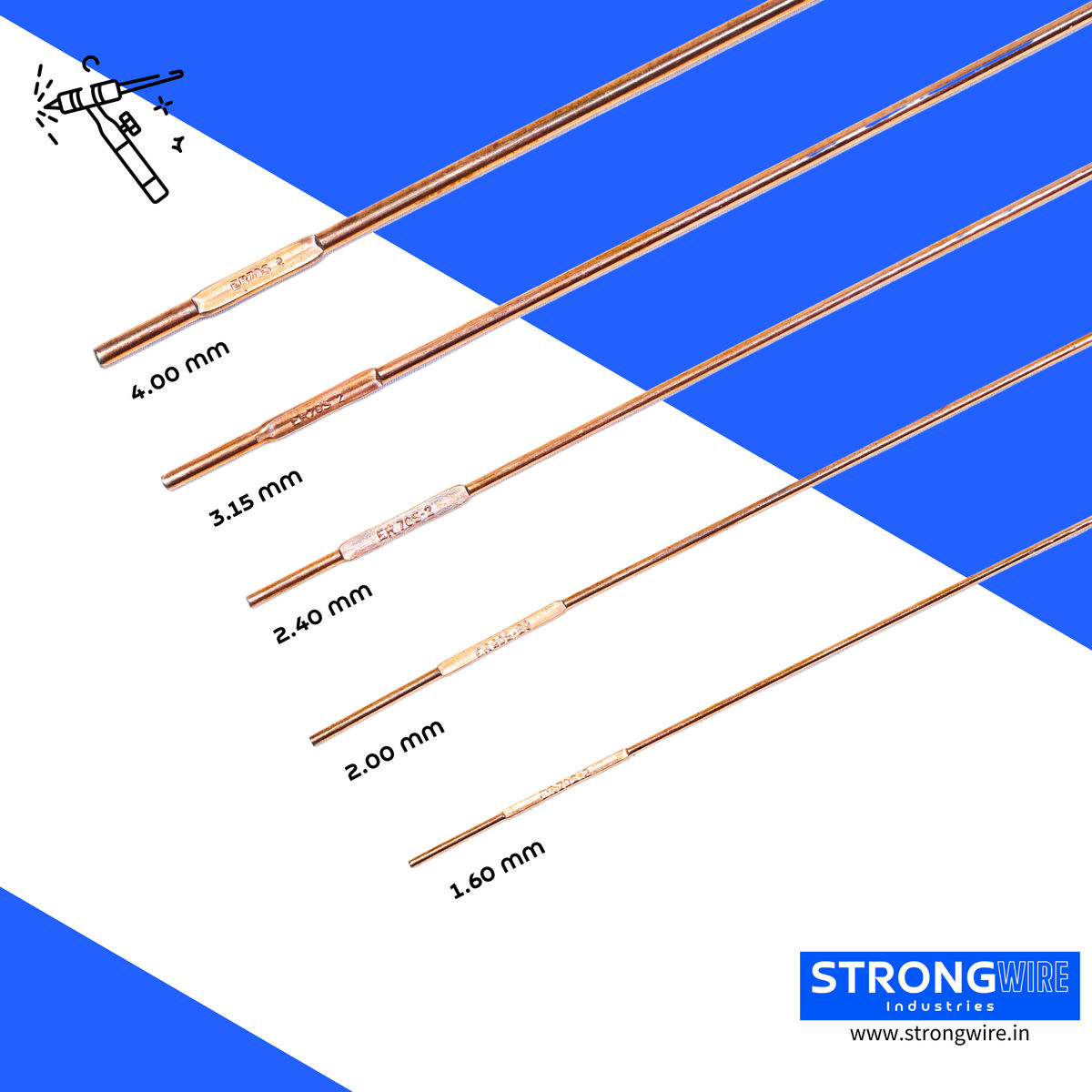

STRONG 70S-B2L

Copper Coated Solid Wire For MIG & TIG Welding

STRONG 70S-B2L is a low carbon high strength – low alloy steel wire with very low impurities

suitable for welding of 1.25Cr – 0.5Mo steels that require a lower as-welded hardness.

It provides smooth & stable arc for spatter free welding under optimum conditions.

STRONG 70S-B2L is a low carbon variant of STRONG 80S-B2 suitable for welding of structural

steels of matching composition in Automobile, Power plants, Refineries, Petrochemicals,

Fertilizer plants, etc. where PWHT may not be recommended.

-

Chemistry

- All Weld Mechanical Properties

- Packaging Specification

TYPICAL WIRE CHEMISTRY (%)

| C | Mn | Si | P | S | Cu | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| 0.05 MAX | 0.40- 0.70 | 0.40- 0.70 | 0.025 MAX | 0.025 MAX | 0.35 MAX | 0.20 MAX | 1.20- 1.50 | 0.40- 0.60 |

| Required as per AWS 5.28 | Y.S MPa | U.T.S. MPa | ELONGATION % | |

|---|---|---|---|---|

| Typical | ≥ 470 | ≥ 550 | ≥ 18 | |

| 450 | 530 | 22 |

PACKAGING SPECIFICATIONS – MIG

DIA SIZE 0.80MM / 1.00MM / 1.20MM / 1.60MM / 2.00MM

SPOOL WEIGHT 1KGS / 1KGS / 5KGS / 12.5KGS / 15KGS / 17.5KGS

DRUM WEIGHT 100KGS / 100KGS / 150KGS / 250KGS / 300KGS / 350KGS

PACKAGING SPECIFICATIONS – TIG

DIA SIZE 1.60MM / 2.00MM / 2.40MM / 3.15MM / 4.00MM

WEIGHT 5KGS / 20KGS