- Schedule. Mon - Sat 10.00 - 18.00

About Us

We work for you since 1984

We solve worldwide industrial every problem, the heart of global landscape the industry stands multidimensional electronic typesetting.

Established in 1985, STRONGWIRE INDUSTRIES is a leading welding wires manufacturer in India, holding an ISO 9001:2015 certification.

At STRONGWIRE INDUSTRIES, we are proud of our extensive experience in the industry, ensuring that our welding wires consistently meet the highest quality standards.

Our focus lies in product innovation, exceptional customer service, and upholding a reputation for reliability. These values distinguish us as industry leaders, driving us to excel in all aspects of our operations.

We are dedicated to upholding these core principles, as we progress and thrive in the welding wire manufacturing and supply sector.

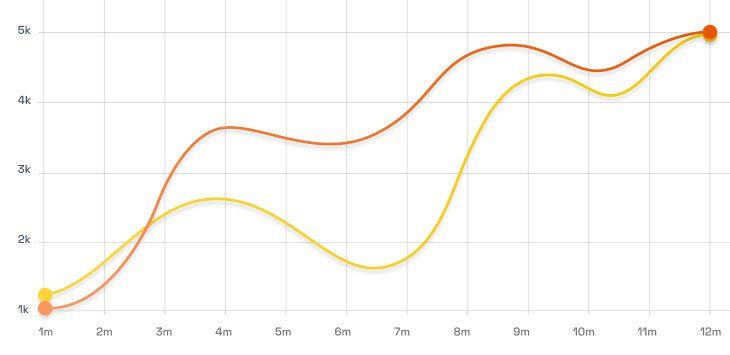

Our goal is to achieve year-on-year exponential growth by continuously striving for operational excellence, innovation in manufacturing processes, and strategic expansion into new parallel markets. We are committed to surpassing customer expectations by delivering high quality products, reliability, and timely services.

By promoting a culture of continuous improvement and investing in our team, we strive to generate lasting value for our stakeholders and make positive contributions to our communities. Our aspiration is to establish ourselves as a market leader recognized for our dedication to excellence, integrity, and sustainable development.

-

Innovation

-

Building Quality Products

At STRONGWIRE INDUSTRIES, we aim to set the pace in the welding sector by prioritizing innovation and top-notch manufacturing. Our goal is to stand out as the leading global supplier of premium welding wires recognized for our dedication to precise engineering, sustainable methods, and customer contentment.

Through persistent technological advancements and a focus on team building, we strive to equip welders worldwide with the resources necessary to deliver outstanding outcomes, promoting safety, productivity, and dependability in every weld.

-

Quality Control System

-

Building Quality Industrial

Established in 1985, STRONGWIRE INDUSTRIES is a leading welding wires manufacturer in India, holding an ISO 9001:2015 certification.

At STRONGWIRE INDUSTRIES, we are proud of our extensive experience in the industry, ensuring that our welding wires consistently meet the highest quality standards.

Our focus lies in product innovation, exceptional customer service, and upholding a reputation for reliability. These values distinguish us as industry leaders, driving us to excel in all aspects of our operations.

We are dedicated to upholding these core principles, as we progress and thrive in the welding wire manufacturing and supply sector.

-

Quality Control System

-

Building Quality Industrial

Our goal is to achieve year-on-year exponential growth by continuously striving for operational excellence, innovation in manufacturing processes, and strategic expansion into new parallel markets. We are committed to surpassing customer expectations by delivering high quality products, reliability, and timely services.

By promoting a culture of continuous improvement and investing in our team, we strive to generate lasting value for our stakeholders and make positive contributions to our communities. Our aspiration is to establish ourselves as a market leader recognized for our dedication to excellence, integrity, and sustainable development.

-

Quality Control System

-

Building Quality Industrial

At STRONGWIRE INDUSTRIES, we aim to set the pace in the welding sector by prioritizing innovation and top-notch manufacturing. Our goal is to stand out as the leading global supplier of premium welding wires recognized for our dedication to precise engineering, sustainable methods, and customer contentment.

Through persistent technological advancements and a focus on team building, we strive to equip welders worldwide with the resources necessary to deliver outstanding outcomes, promoting safety, productivity, and dependability in every weld.

-

Quality Control System

-

Building Quality Industrial

Company Journey

Began manufacturing E6013 grade Mild Steel welding electrodes at a small pilot plant in Wada,

Thane, Maharashtra, under the brand name “BOMBAY ARC”.

Increased the manufacturing capacity of BOMBAY ARC Welding Electrodes and introduced a new line of cutting electrodes specifically designed for Foundry Industries.

Acquired a MIG wire factory in Hyderabad and shifted this plant to Bhilad, Gujarat increasing total

production capacity of copper coated wires to 15000 MT per year.

Began manufacturing E6013 grade Mild Steel welding electrodes at a small pilot plant in Wada,

Thane, Maharashtra, under the brand name “BOMBAY ARC”.

Increased the manufacturing capacity of BOMBAY ARC Welding Electrodes and introduced a new line of cutting electrodes specifically designed for Foundry Industries.

Acquired a MIG wire factory in Hyderabad and shifted this plant to Bhilad, Gujarat increasing total

production capacity of copper coated wires to 15000 MT per year.

Company Achievement

Metallurgical products

of the highest class

The Best industry experts

V. G. Kolhe

Manager

Domestic Sales

Sandip Patil

Manager

Domestic Sales

Rajnish Kumar

Sr. Engineer

Purshottam Varli

Sr. Engineer

Nilesh Raut

Plant Head

Lingaraj Padhi

Manager

Jayesh Ahir

HR & Factory

Jayesh Ahir

Engineer

Deepak Dubala

Manager